Legalized marihuana has been around for almost a decade in America. Not just as an approved medicinal drug but also as a socially acceptable form of relaxation. It’s being legislated much the same as alcohol and tobacco. Washington, Oregon, and Colorado were the pioneers in permitted the commercialized production sale of marijuana. Since then, 27 states and D.C. have voted to decriminalize cannabis, including California, Massachusetts, and Nevada.

Federally, the laws surrounding legally grown marijuana don’t allow an interstate trade of cannabis, but that’s bound to change. Cannabis products will be traded soon across state lines as well as internationally. Canada, which is America’s largest trading partner, has been growing and selling medicinal marijuana on the open market since 2001. It was later updated in 2016 and has been legalized for recreational use since 2018.

What used to be a secretive, black market sub-culture has emerged into a respectable, professional, and extremely lucrative agricultural industry.

Marijuana grows naturally in warmer climates. However, to keep it in lucrative production, no matter the location, greenhouses must be used. These greenhouses rival anything used in sophisticated indoor farms that grow fruit and vegetables. They have advanced building systems that incorporate steel-structure housing climate-controlling devices. For example, proper lighting replicates the sun and capitalizes on the plants’ natural growing cycles.

High-yield crops are produced in indoor microclimates. These are produced with the help of computerized watering and nutrient delivery, advanced air conditioning, ventilation systems, and disease and pest controls. And, of course, being held in a safe and secure environment ensures control.

All this high-tech and high-dollar effort results in delivering a tremendous rate of return on investment. Now that the legal penalties are lifted, the marijuana industry is gaining above-ground respectability. People from all walks of life are getting into the “green-gold” movement and building their own cannabis farms. That might be in a small closet within their home or an economical marijuana grow-house in their backyard. A farm could even be a large commercial-scale, free-standing steel structure in a legally zoned industrial area.

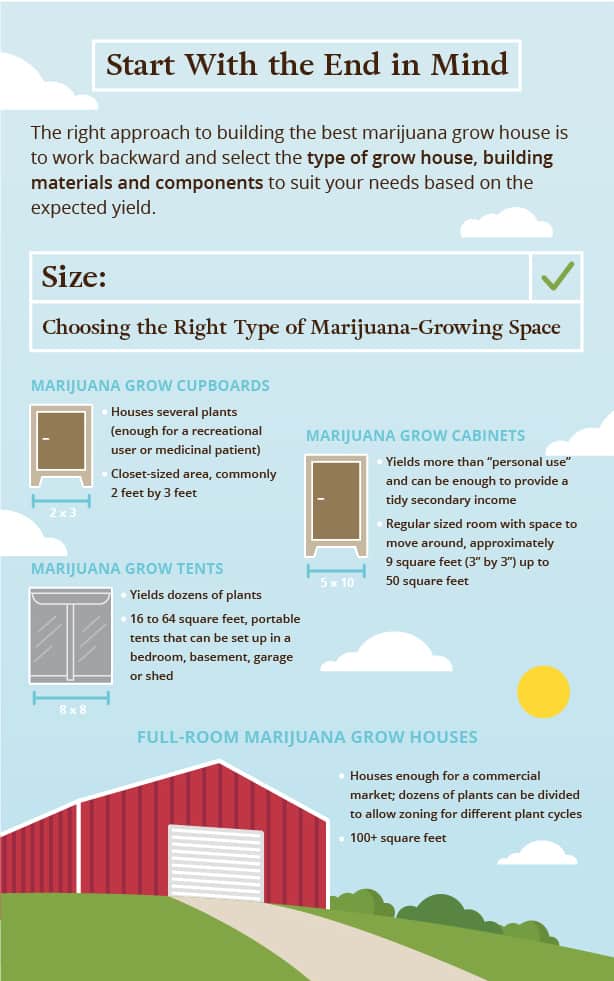

Experienced marijuana growers know that the right approach to building the best marijuana grow house is to work backward. They start with the end in mind and select their building materials and components to suit their needs.

This approach to growing marijuana is quite simple. It starts with a basic knowledge of the marijuana plant’s scientific properties. Then accommodates the plant’s needs to produce the best flowering buds.

Basically, cannabis plants require water, nutrients, heat, humidity and regulated lighting that replicates the natural environment it needs to survive and reproduce.

In giving marijuana plants that environment, it is crucial to building a grow-house that can provide all that. A successful marijuana grow-house starts with a plan of how to get there. Simply put, the higher the expected yield, the more light and space the plants need. However, when light is increased, so is heat, and this requires managing the heat with cooling and ventilation systems.

The bigger the marijuana growing operation is, the more systems will be needed to manage it, and it costs more. With this in mind, here is a general guide to building a marijuana grow-house.

The horticultural name for marijuana, or the hemp plant, is Cannabis Sativa. It is found naturally in warmer climates, but it has been cultivated for centuries. It’s primarily for using its fibers to make fabrics and a host of articles. Additionally, the intoxicating ingredients and the medicinal benefits of cannabis ingestion are long proven. However, marijuana has only recently been accepted by mainstream American culture.

The active ingredients in marijuana are tetrahydrocannabinol or THC, as well as cannabinol oils. It is THC that gives the “buzz” as well as providing the healing relief which marijuana is well known for. The source of THC comes from the plant’s flower or bud, and it is only the female plants that flower. Having a male plant in a marijuana grow house is disastrous. Pollination will stop the THC production and kill the crop’s value.

Marijuana plants grow, bloom and die on a predictable cycle that can be manipulated in a controlled grow house climate.

New plants can be started from seeds, although most commercial or larger hobby grow-houses use marijuana clones. Then, they are cut off from a mother plant and rooted in a solution. Once the plants are sturdy, they are transplanted to either a growing medium or a hydroponic system where the roots are immersed in nutrient-rich water.

The next phase of a marijuana plant’s life is the vegetation stage.

Here, it reaches maturity by growing its stalk, stems, and leaves. This requires an exact light cycle of sixteen hours of bright light in a blue light spectrum that simulates spring and summer. Cannabis plants must get eight hours of total darkness before the light is applied again. As “fall” approaches, the amount of light is decreased to exactly twelve hours of daylight and twelve hours of darkness. The light spectrum is changed to orange, forcing the plant to go into its reproductive phase to flower.

Marijuana flowers are not colorful, showy displays like annual bedding plants. The flower is a spikey “bud” that contains the valued THC compounds. Commercial marijuana plants do not contain seeds unless they are specifically being raised for seeds. Seedless plants are known as “sensimilla,” The buds are harvested just before their THC is naturally released in the form of resin or oil – which is what hash is made from.

The valuable buds are dried, then trimmed, and packaged for sale while the leaves and stalks are left to die and be composted or otherwise destroyed. Other extracts can be made from cannabis flowers, but most buds are rolled into “joints” and smoked or blended into all sorts of baking, teas, and edibles.

Controlling a marijuana-growing environment starts with the structure. Advanced commercial marijuana greenhouses can be huge operations, built-in converted warehouses. They can also be in specially designed steel buildings that contain different grow rooms and support sections. A number of these industrial grow operations, for example, have many rooms dedicated to housing plants that are in different life cycle stages, from clones to vegetation to flowering.

These big grow houses have special rooms that house mother plants as well as developing clones. Grow houses can support hundreds of plants on automated racks and trays as they advance in size. Once at the optimal size, the plants are cut down and hung to dry in micro-controlled rooms in heat and humidity. Commercial operations have additional rooms that are surgical-clean where the buds are trimmed, weighed, and packaged.

Outside of the production rooms, the larger marijuana factories have mechanical rooms that are also separate. Here, large-scale air conditioners pump air to the grow-rooms injected with carbon dioxide (CO2), vital to plant health. Large tanks hold water enriched with nutrients and delivered through sophisticated irrigation systems and computer-controlled to drip the exact amount of hydronic to each plant at exactly the right time.

Lights in the grow rooms are switched on and off by timers housed in control centers. Air is filtered by ducted recycling systems that keep the pungent odor of flowering plants under check and reduces the risk of outside infiltration by molds, spores, pollen, pests, pathogens, and disease. Dust and dirt are the enemies of grow houses, and this is constantly being mitigated by disinfecting not just the rooms but also the entire facility.

And, of course, there’s security. All legitimate marijuana grow houses are regulated to have security to prevent internal theft and mitigate exterior threats. Security measures can be as simple as locks, alarms, and video cameras all the way to integrated and computerized security management systems that require biometrics to verify entry passes and retain several years of video surveillance on massive servers.

Large marijuana grow-houses are known as, Closed Growing Environments, or the CGE method. These massive CGE grow houses also require massive capital investments, with some of the big players raising millions of dollars in publicly traded ventures. Of course, they are returning millions of dollars in revenues. Still, the reality of the marijuana-growing world is that most pot-growers operate on micro-scales that don’t involve thousands of square feet of structure nor hundreds of employees.

It is all about economies of scale, and it’s what’s expected of the yield that drives the plans for a marijuana grow-house. Here are several marijuana grow-house ideas:

The simplest and most common marijuana grow house is a small cupboard located in the cannabis farmer’s home. Usually, it is in a secondary bedroom that has low traffic and meager cost. Most cabinets are closet-sized and only house several plants. Spaces of two feet by three feet are common, and these normally require one small light and simple hand watering.

The yield from one cupboard can be significant, though. A several-month growing season can raise enough buds to provide a recreational user all they can smoke or a medicinal patient needed for treatment.

The next step up in marijuana grow house options is a marijuana grow cabinet. This is a larger space with enough room to move about, yet it is still contained within a regular-sized room. Often these cabinets are located in a basement or outbuilding and range in space from three feet by three feet (nine square feet) up to 50 square feet.

The largest grow cabinets require significant lighting and electrical requirements, which typically maximize the power services to an existing room. Yield from a cabinet can be more than justified as “personal use” within the law but can return a tidy secondary income for a grower.

These portable marijuana grow-houses are very popular for their return on investment. They are tents that fold out to a free-standing structure set up in a bedroom, basement, garage, or even a storage shed. Sizes range from 16 square feet up to 64 square feet and can accommodate dozens of plants.

These fabric grow tents are completely lightproof for a controlled environment and are blacked-out on the exterior yet highly reflective on the inside. They allow the grower to integrate automated watering and filtered ventilation systems at an affordable price.

Multiple marijuana grow-tents are often used in multiple units that house crops at various stages of development. Still, they are limited in size due to structural support and have a limited lifespan. Moving the tents take a toll, as does continual washing to maintain a healthy mold and pest-free interior.

Full rooms of 100 square feet or more are beyond the hobbyist’s reach. These rooms are also attached to a significant monetary outlay and a great amount of time consumption required to run them.

Basements or cellars are good choices for full-room grow houses, as the underground temperature from the earth is cooler and more stable than an above-ground room, especially an attic. Full rooms can accommodate dozens of plants and can be divided to allow zoning for different plant cycles.

Full-room grow houses also require more electrical and ventilation supply than can be provided without significant alterations to an existing structure. This is why many marijuana growers turn to specially designed, freestanding steel structures. A serious grower upgrading from a small operation and expanding into the increasingly lucrative commercial marijuana market is wise to spend the time and the funds to develop a dedicated and trouble-free grow house.

Properly designed full-room marijuana grow houses are built with the proper components that include the correct insulation, ventilation, lighting, automated controls, and a safe and secure environment.

Insulation is a critical component in a trouble-free and productive marijuana grow-house. This is particularly true in steel-framed buildings where high humidity and warm temperatures cause water vapor to condense against the cooler steel roof supports. It can actually rain inside grow houses that are not insulated properly with the correct R-value and suitable materials.

The best insulation, by far, is a spray-on closed-cell foam, and the worst is fiberglass batts. Soy-based insulation products are also excellent at being mold and disease-resistant. Soy is lightweight, inexpensive, and highly fire-resistant. Building codes may be restrictive for insulation choices, and the grower must comply if the grow house is a legitimate and licensed venture.

Insulation also has more responsibility in a marijuana grow-house than simply keeping the warm air in and the cold out. Insulation is part of the entire building envelope that blends the exterior sheathing, roof system, and flooring, and it works to keep the closed growing environment airtight and condensation free.

Additionally, insulation in a grow house should act as an interior wall surface that reflects light on the plants and capitalizes on the artificial light, and sealing the grow room from outside light pollution when the plants are resting. Suitable reflective surfaces can be flat white paint that has little light absorption or a Mylar wrap product. Foil is a poor choice as it’s difficult to keep smooth. The crinkles or irregularities on foil cause light to be unevenly reflected and creates “hot spots” which burn the plants.

A properly insulated grow house relies on mechanical ventilation to regulate the air temperature, humidity, and the inevitable odor which starts once the marijuana plants are in bloom.

Besides water, nutrients, and light, the most important ingredient for growing healthy marijuana is constant fresh air rich in carbon dioxide. Like all plants, marijuana takes in carbon dioxide and releases oxygen back into the air. A deficiency in carbon dioxide reduces the plants’ ability to grow and flower, which destroys their value.

Air quality doesn’t just depend on carbon dioxide, though.

Growers must keep the air at a constant temperature.

Preferably below 85 degrees Fahrenheit and have a consistent relative humidity of approximately 70 percent.

With the heat from the “grow-lights” and the constant mixture introduced by the water requirements, keeping a balance of just the right air temperature and humidity can be difficult. A general rule is having 450 cubic feet per minute of air exchange for every 1,000 watts of illumination.

Marijuana plants are sensitive to abrupt and drastic changes to their environment. Any great fluctuation in temperature, humidity, and exposure to light can quickly ruin a crop, causing it to fail in flowering or die altogether. A properly balanced air conditioning unit that regulates airflow is essential in a good marijuana grow-house.

The location of the air-handling unit and any auxiliary fan units is critical as well. Just as plants suffer when too compact a crop does not allow air movement between and around the plants, cannabis needs the CO2-rich air to enter from the lower side of their leaves and the oxygenated air to exhale from above.

Plants also use less carbon dioxide during their dark cycles, which makes CO2 augmentation even more tricky. Many grow houses use CO2 generators that help keep the same balance in a closed environment as nature would provide in the wild.

Also, marijuana plants require clean air, making scrubbers, ozonators, and charcoal filters mandatory for larger productions. These mechanical ventilation additives also work to control the flowering stage smell. Investing in the right size air handling equipment with the correct components is essential for building a marijuana grow-house.

Now for the subject of lights in marijuana grow houses. The right amount, specific type, and proper size of artificial lighting are critical in designing a marijuana grow-house. The number of lights and their placement depends on the number of plants harvested and the size of the grow house.

A rule of thumb for lighting is an average of 800 watts of high-intensity illumination for every 10 square feet of floor space. Marijuana grow-lights are commonly metal halide (MH) or high-pressure sodium (HPS). But some specific applications like cloning may need an induction, light-emitting diode (LED), or plasma lights.

Proper placement of lights is vital. Lights too close to the plants may burn them. In comparison, lights in the distance won’t deliver enough rays to allow photosynthesis, which plants turn light into energy.

Life can’t exist without water, and this applies to marijuana plants as well.

Small marijuana grow-houses may get by with simple hand watering on an as-and-when-required basis. But this vital task can get overly laborious with large-scale grow operations. Many grow houses are designed and built with automated systems that use computer-controlled delivery of specific amounts of water to each plant when it’s needed. Overwatering can be just as harmful to marijuana plants as under-watering.

Sophisticated irrigation systems that work on automated demand are available. They include the precise mixing of nutrients, which again vary on where the plants are in their life cycle. Water sources can be expensive or scarce, depending on the location of the grow house. Some operations tap into civic services and are metered. Others tap into drilled or artesian wells, and some of the ‘green’ grow houses use recirculation and exterior storage tanks that trap and store rainwater.

Planning and utilizing an irrigation system is as important as planning what type of structural material will be used in a marijuana grow house.

Moving back to the initial planning stage in designing a marijuana grow-house. The first consideration other than the size and the location of what’s to be built is the materials used in the grow-house structure.

For stand-alone grow rooms, there are several choices, but wood is a poor material. Wood is susceptible to high moisture that’s found in marijuana grow houses. It can quickly twist and rot, presenting a source of crop-killing mold. Wood is also highly combustible and should be ruled out for that reason alone.

Plastics and other composite materials can support a grow-house structure, but they are expensive and hard to obtain. Concrete is an option, but cement products like poured-in-place walls or masonry blocks are cumbersome and pricey.

By far, the best marijuana grow-house material to use for the structure is steel. Steel framed buildings are cost-effective and quick to erect. They are non-combustible, won’t twist, rot or contribute to internal pathogens. Steel buildings can be designed from tiny units, like garden sheds with steel wall panels and roofs. Or buildings can be huge, clear-span structures that are made to house thousands of plants.