So you’re deciding on installing a metal roof, that’s great! You will have the benefits of a durable roof that can last a very long time in all environments. Deciding to go with a metal roof is the first of many decisions you will have to make for your roof and it can feel a bit overwhelming at times. The right choice for you will depend on your budget, build-speed requirements, location, and the lifespan you want for your roof.

Metal roofs encompass multiple types of metals, from steel, copper, and aluminum being the most popular. If you are interested in learning more about which material is best equipped for your roof check, out our previous post: Asphalt Vs. Metal Roofs.

So now that you have an idea of what metal best suits your roof you will also need to consider what kind of metal roof panel system you want. Two of the most popular metal roof panel types are screw-down metal roofs and standing seam, or “exposed fastener” metal roofs. Both of these are great systems. Choosing the right one can be the difference between a long-lasting roof and a roof that has avoidable issues.

To make sure you choose the right roofing system, we decided to break down and determine what metal roof panel system fits your specific needs.

First, let us go over what each roofing system entails.

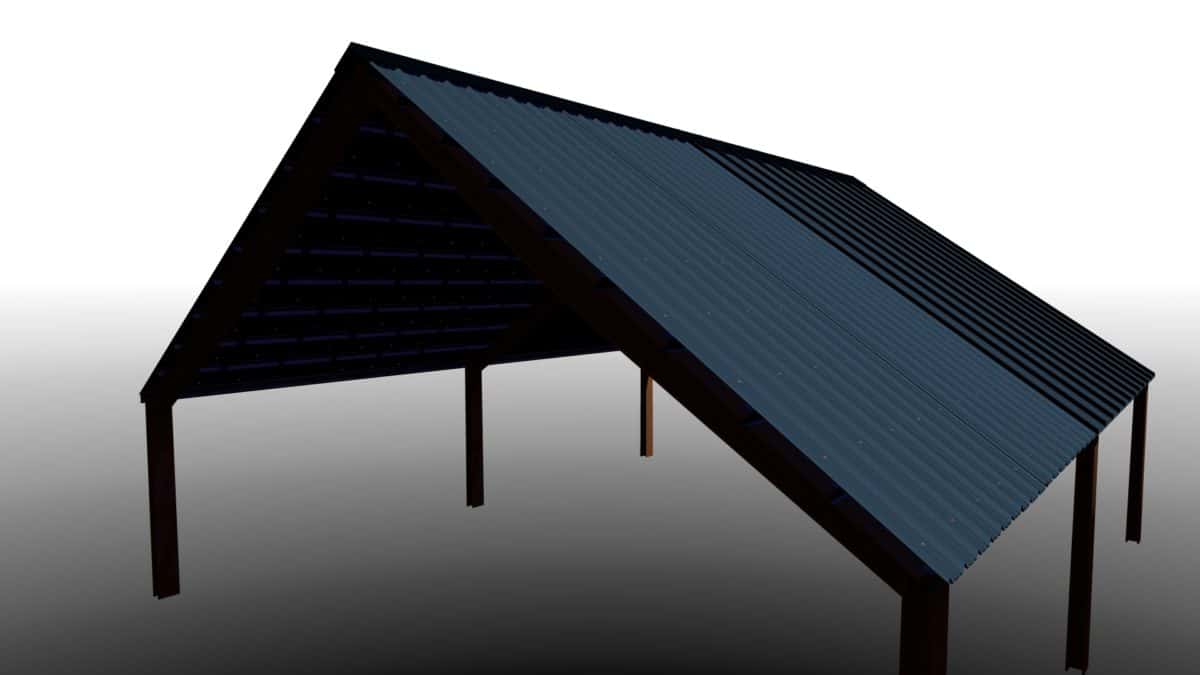

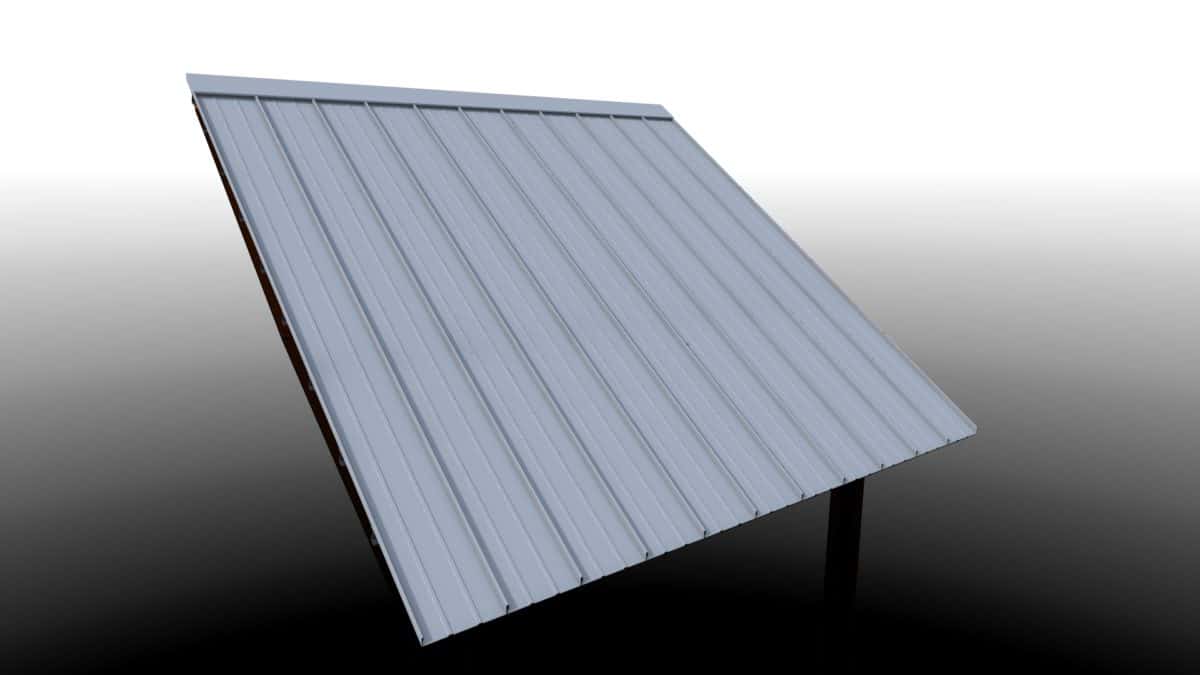

Screw-down metal roofing is a metal roof held together with screws that hold the roof in place. Screw-down metal roofs use many individual metal screws to secure rigid metal roof panels to a structure. It is the most basic metal roofing system. You can find screw-down metal roofs usually installed in garages, barns, and commercial buildings.

The installation process is quick and easy, not requiring any specialized contractors. Installation only requires a simple fastened to the frame with screws. Because it’s so basic and easy to install, it is one of the cheapest metal roofing options out there.

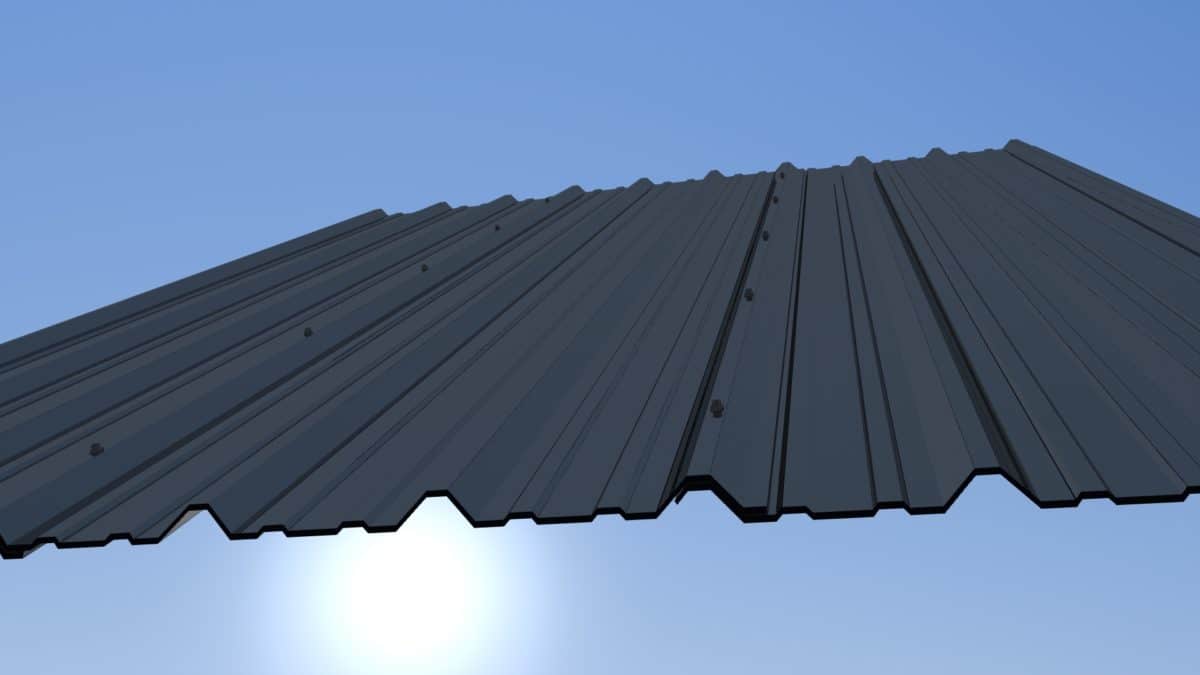

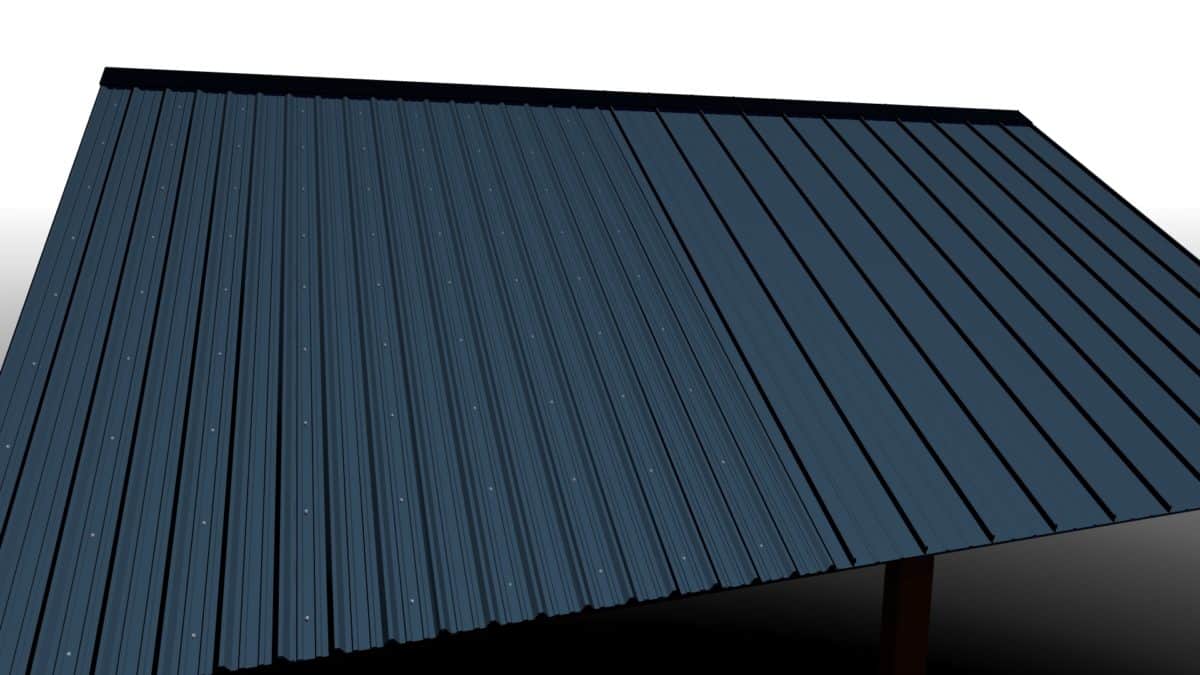

Standing seam metal roofs are not fastened by screws, but rather, are interlocked, or hooked, onto one another with each panel. The standing seams are between 12 to 24 inches wide depending on the panel type and the type of aesthetic you prefer.

Fastening is achieved through a 1-inch bend that allows for interlocking. This fastening allows the standing seam metal roofing to move, expand, and contract without breaking tight seals. The fastening on the metal panel system is hidden below the surface of the panel by using a clip or nail flange system. A hidden system is a big plus eliminating the faulty or improperly fastened exposed systems.

Let’s compare the two!

Both roof systems have their place in building construction.

Standing Seam Metal Roofs are usually installed in spaces that will have a vast temperature change. These roofs are also used for their aesthetic appeal. The screws on the standing seam metal roof are hidden between overlapping seams, making them more aesthetically pleasing.

Screw-Down Metal Roofs have great appeal in price and are used in garages, porches/patio covers, barns, sheds, carports, etc. These roofs can be installed anywhere.

Standing Seam Metal Roofs usually last between 30 and 50 years with very minimal to no maintenance, if installed correctly. You will experience fewer leaks and issues with a standing seam roof thanks to its thermal responsiveness.

Standing seam panels provide superior wind and weather protection. If you are in an area that is particularly windy or prone to hurricanes and tornadoes, you will feel safe knowing that these roofs have great wind uplift performance.

Wind uplift is the suction created by wind forces as the air moves parallel to the roof’s surface. In extreme wind events such as hurricanes and tornadoes, uplift can pull panels and shingles off buildings.

Screw-Down Panels require maintenance around every five to ten years to avoid these issues and other issues:

If there is no maintenance done on these roofs it can lead to leaks or a storm tearing the roof off.

When deciding to go with a metal roof, you must be aware that metal expands and contracts whenever there is a temperature change. This is known as thermal expansion. When exposed to hotter temperatures, your metal roof will expand, when exposed to a cooler change in temperature, your metal roof will contract.

This isn’t an issue if you install the correct roof for your building.

Standing Seam Metal Roofs are a lot more thermally responsive, having no issues expanding and contracting with a temperature change. Like we mentioned before, fastening is achieved through a 1-inch bend that allows for interlocking. This fastening allows the standing seam metal roofing to move, expand, and contract while the clips stay fastened. The panel glides back and forth and there are no breaking tights seals or potential leaks.

This is why we recommend using standing seam metal roofs in overheated areas such as living spaces since these roofs can handle vast temperature changes without any issues!

Screw Down Metal Roofs rely on hundreds of screws to be installed and maintained properly. This screw-down method is NOT ideal for vast temperature changes since it restricts the metal from expanding and contracting naturally. These roofs are constricted, putting pressure on the screws causing them to potentially break off if they aren’t replaced and maintained every 5 to 10 years. When replacing these screws, you must make sure to replace them to the next size up to prevent them from breaking off in the future.

With this in mind, we recommend customers using standing seam panels on their homes. Screw-down roofs can lead to some maintenance in the future and will increase the chances of leaks.

Cost is always a factor that needs consideration when installing a new roof. With any roofing system, you will want to consider both upfront costs such as initial installation costs as well as maintenance and repair costs.

Standing Seam Metal Roofs will cost twice as much if not more than a screw-down panel roof. Standing seam metal roofs require a thicker gauge of metal as well as a specialized craftsman for proper installation. Both material and labor costs are on the steeper side.

Like we said before, standing seam metal roofs require little to no maintenance. If installed correctly, it could save you significantly more down the road.

Screw Down Metal Roofs are pretty much the most basic roof you can install, making them the cheapest metal roofing option you will find in the market. These roofs are pretty quick and easy to install and don’t require a skilled craftsman.

While you might save money on screw-down metal roofs initially, the long-term maintenance cost is significantly higher than standing seam metal roofs. If you do, you will incur significantly more cost down the road. This will include some maintenance and repairs on leaks.

Knowing what roofing system fits your needs will save you significant headaches down the road. We hope this article helps you select the roof that applies best to your application.