Panels and fasteners

Find panels in our selection of steel building materials, including Superspan X, Low Rib X, Monarch X, Cor-Span X, 7.2 Rib, Super Seam 24, Weather Lok 16, Accent Panels, Liner Panels and more, as well as a series of effective and durable fasteners.

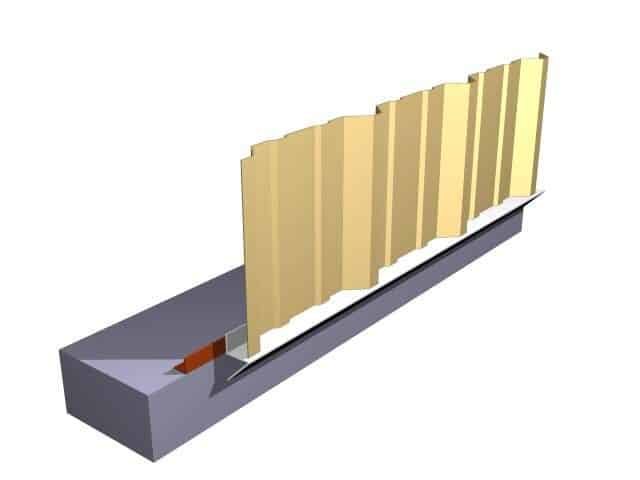

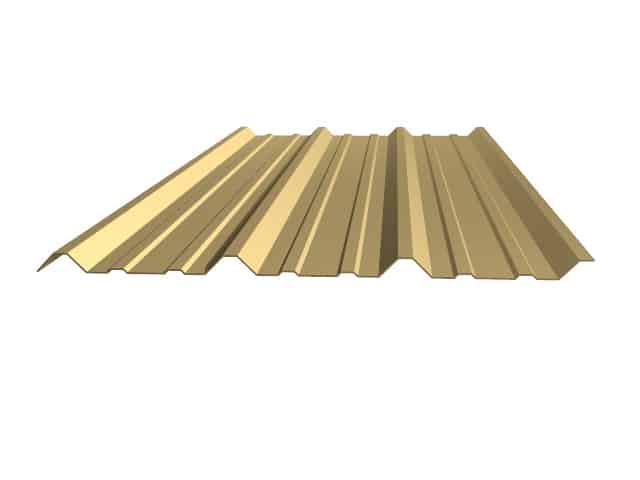

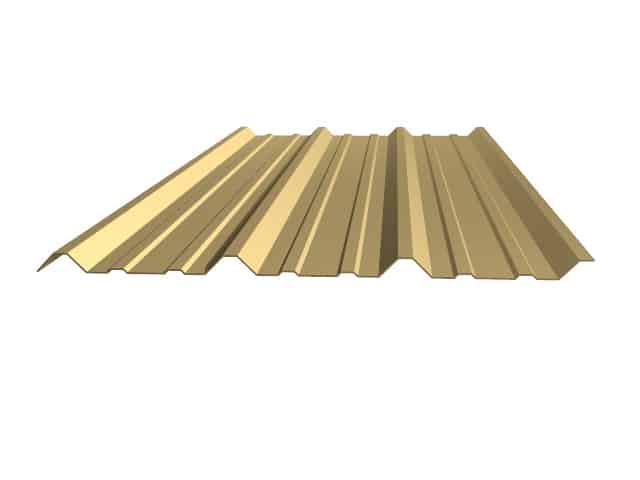

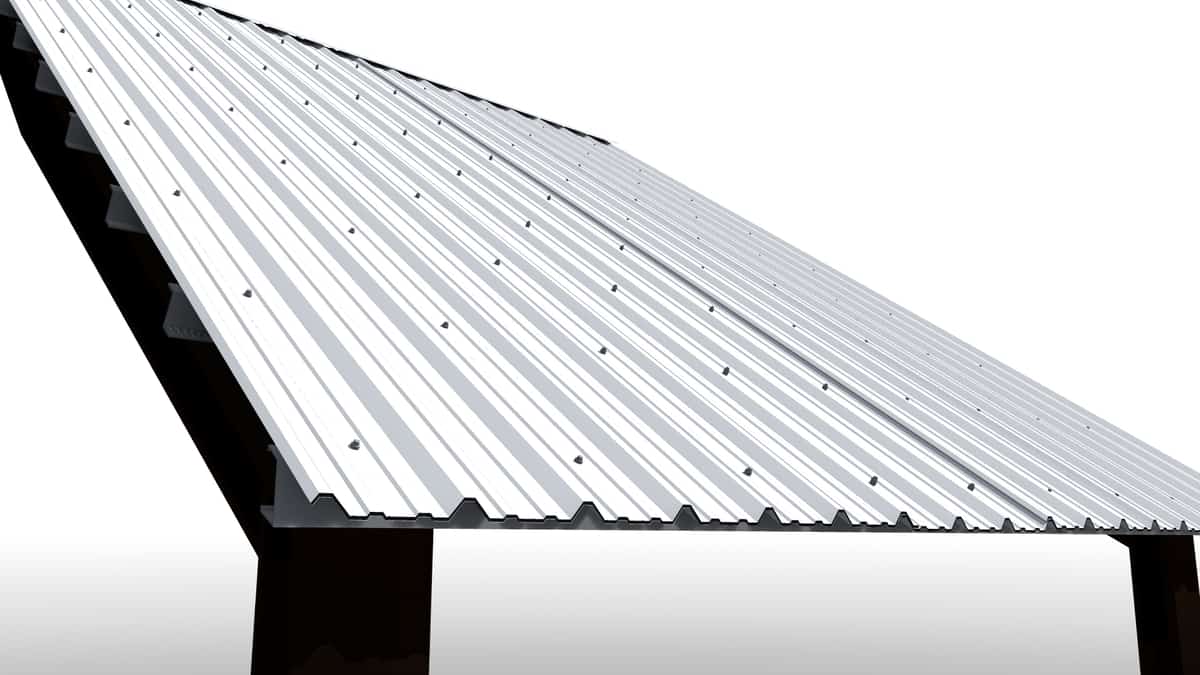

Super Span X

Superspan panels are our most popular seller. These panels are typically manufactured in 26ga steel with yield strength of 80,000 psi. Other gauge material such as 24ga and 29ga are also available depending on the application. The Superspan X panel was specifically designed to provide superior strength while being very cost effective. This panel is available in over 20 different colors. The base metal is galvalume, which is a zinc-aluminum coating that provides excellent corrosion resistance. This panel comes with a standard 40 year paint warranty.

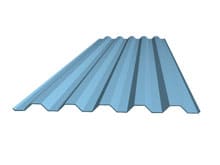

Low Rib X

Low-Rib panels are used when trying to achieve a low profile look. These panels are typically manufactured in 26ga steel with yield strength of 80,000 psi. Other gauge material such as 24ga and 29ga are also available depending on the application. The Low-Rib X panel was specifically designed for strength without the need for deep ribs. The panel ribs are only 3/4" high and spaced 6" on center. The Low-Rib panel is a great alternative to the Superspan panel and just as cost effective. This panel is available in over 20 different colors. The base metal is galvalume, which is a zinc-aluminum coating that provides excellent corrosion resistance. This panel comes with a standard 40 year paint warranty.

Monarch X

The Monarch panel profile is very unique. The main ribs are 1" high and 12" on center. The unique profile is used to really make a statement and visually set your building apart from the rest. The panel screws are also partially hidden by the nature of the profile. These panels are typically manufactured in 26ga steel with yield strength of 80,000 psi. The Monarch panel is also available in 24ga for higher wind applications. The Monarch X panel was specifically designed for strength while providing a unique versatile look. The Monarch panel is a great alternative to the Superspan panel and just as cost effective. This panel is available in over 20 different colors. The base metal is galvalume, which is a zinc-aluminum coating that provides excellent corrosion resistance. This panel comes with a standard 40 year paint warranty.

Cor Span X

The Cor-Span X panel profile has been around for many years. The Cor-Span profile used to be the main panel used in any steel sheeting application. Though not as popular nowadays, this panel can be used to make your building stand out from the rest. The main ribs are 7/8" high with a continuous wave pattern. The panel screws are also partially hidden by the nature of the profile. These panels are manufactured in 26ga steel with yield strength of 80,000 psi. The Cor-span panel is a great alternative to the Superspan panel and just as cost effective. This panel is available in over 20 different colors. The base metal is galvalume, which is a zinc-aluminum coating that provides excellent corrosion resistance. This panel comes with a standard 40 year paint warranty.

7.2 Rib

The 7.2 Rib panel profile is similar to a Low-Rib panel with a much deeper corrugation. The main ribs are 1-1/2" high and 7.2" on center. This panel is used to make an architectural statement. The 7.2 Rib panel can give your building a very heavy duty, industrial look. These panels are typically manufactured in 26ga steel with yield strength of 80,000 psi. The 7.2 Rib panel is also available in 29ga, 24ga and even 22ga when strength is a top priority. With all these gauge options, there is no application that this panel would not fill. The 7.2 Rib panel was specifically designed for strength while providing a unique versatile look. This panel is a great alternative to the Superspan panel for any type application. This panel is available in over 20 different colors. The base metal is galvalume, which is a zinc-aluminum coating that provides excellent corrosion resistance. This panel comes with a standard 40 year paint warranty.

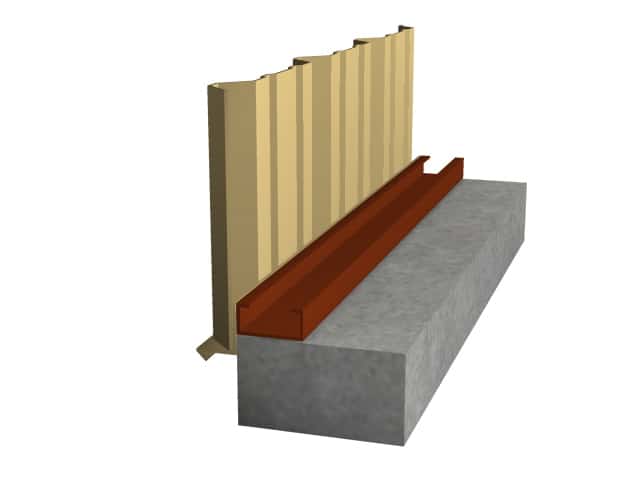

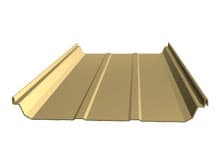

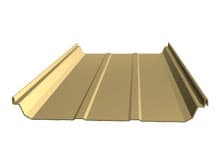

Super Seam 24

The Super Seam 24 panel is our most popular standing seam roof system. Standing seam roof systems are considered the best in the industry for their appearance and weather tightness. The Super Seam panel is a trapezoidal shaped profile with a 3" high rib seam and 24" in width. These panels are manufactured in 24ga steel with yield strength of 50,000 psi. This panel comes standard with a Kynar 500 Fluoropolymer finish which is considered the best finish in the industry. The greatest feature of the standing seam roof system is that the panels are fastened to the roof by clips that are under the panel. This type of connection eliminates the need for screws going through the panel thus giving you incredible weather tightness. This panel comes in either a mechanically seamed or snap seam versions. The mechanical seam version will require the use of a seaming machine to lock the roof into place. The snap system only requires the panels to be snapped together. The mechanical panel is recommended because of its greater strength over the snap panel. The Super Seam panel comes with a standard 35 year paint warranty. This standing seam panel is the ultimate in weather protection and panel quality. If you are looking for a top of the line metal roof system, this is it!

Weather Lok 16

The Weather Lok 16 panel is our best looking standing seam roof system. Standing seam roof systems are considered the best in the industry for their appearance and weather tightness. The Weather Lok panel has a flat profile with a 2" high rib seam and 16" in width. These panels are manufactured in 24ga steel with yield strength of 50,000 psi. This profile is the strongest standing roof system in the metal building industry. This panel comes standard with a Kynar 500 Fluoropolymer finish which is considered the best finish in the industry. The greatest feature of this standing seam roof system is that the panels are fastened to the roof by clips that are under the panel. This type of connection eliminates the need for screws going through the panel thus giving you incredible weather tightness. This panel comes in either a mechanically seamed or snap seam versions. The mechanical seam version will require the use of a seaming machine to lock the roof into place. The snap system only requires the panels to be snapped together. The mechanical panel is recommended because of its greater strength over the snap panel. The Weather Lok panel comes with a standard 35 year paint warranty. This standing seam panel is the ultimate in weather protection and panel quality. If you are looking for a top of the line metal roof system, this is it!

Accent 11

The Accent 11 panel is our best looking soffit or liner panel because of its flat appearance and the absence of visible screws. The Accent panel has a flat profile with a 1" high tongue and groove interlock and 11" in width. These panels are manufactured in 24ga steel with yield strength of 50,000 psi. All the fasteners are hidden because of the unique tongue and groove interconnect system. This profile will give your interior wall or soffit a very sleek appearance. This panel comes standard with a Kynar 500 Fluoropolymer finish which is considered the best finish in the industry. The Weather Lok panel comes with a standard 35 year paint warranty.

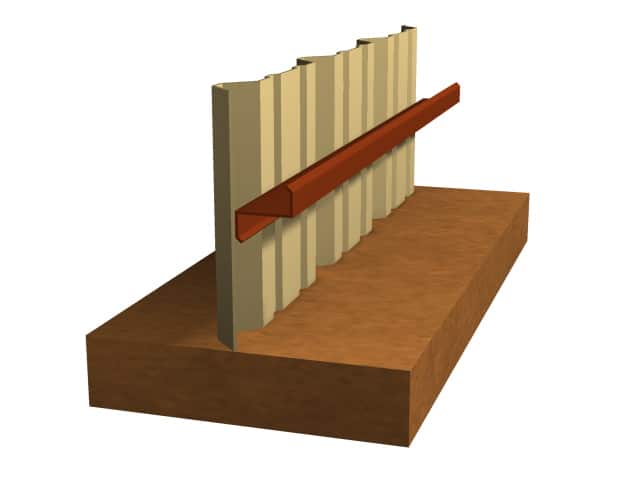

Liner Panels

Liner panels are perfect for finishing off the inside of your building. Liner panels are available in 29ga, 26ga, and even 24ga, depending on the application. Our most popular liner panel profiles are the Super Span, Low Rib and Accent 11 panels. Liner panels are used on the inside of the walls and roof to easily and economically finish off the interior of your building. These panels are available in over 20 different colors. The base metal is galvalume, which is a zinc-aluminum coating that provides excellent corrosion resistance. These panels come with a standard 40 year paint warranty.

Long Life Self Drillers

All of our buildings come standard with Long Life self drilling / self tapping screws for all wall and roof panels. The screw heads are also painted to perfectly match the panel color, allowing them to blend in. MBMI only supplies ZAC type fasteners which are Zinc Aluminum Coated. This superior finish is guaranteed against rusting! Our screw heads have an encapsulated rubber washer which provides a completely weather tight seal when screwed down. Some of our competitors do not supply ZAC screws thus voiding your panel warranty! Purchase your steel building from MBMI and you will receive top of the line quality down to the last screw.