Industrial metal buildings have changed how many manufacturers approach facility planning. These steel structures now support a wide range of operations, from automotive plants to fabrication shops. As demand grows for efficient, scalable solutions, industrial metal buildings continue to gain traction across the manufacturing sector. Their appeal comes from a combination of durability, layout flexibility, and cost-effective construction. Together, these features have made steel buildings a practical choice for today’s evolving industrial needs.

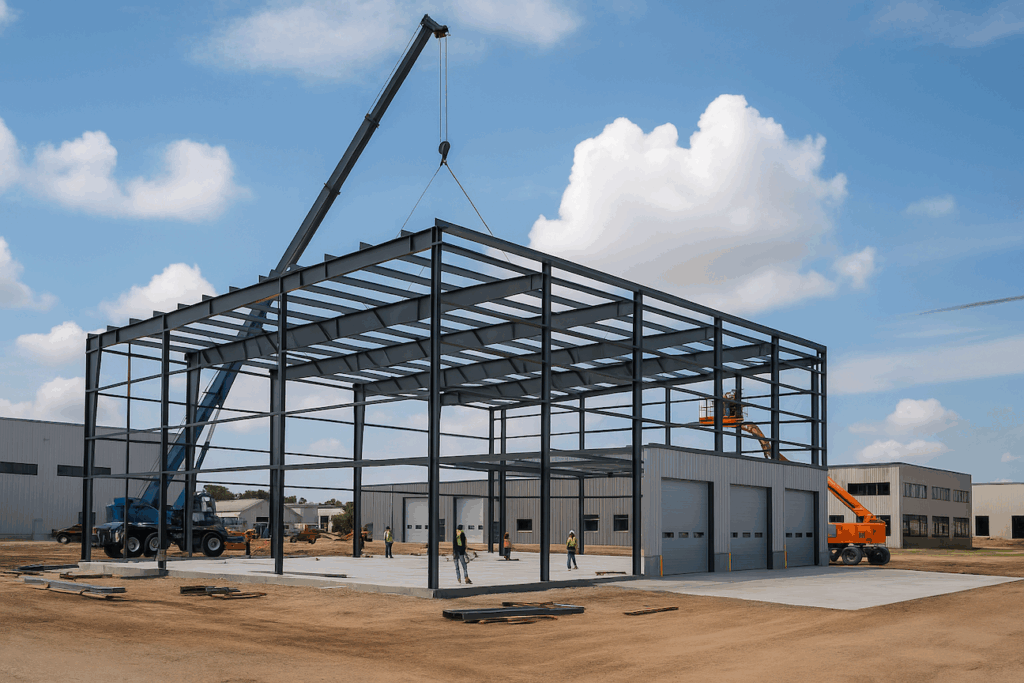

Pre-engineered metal buildings are often used in settings that require structural resilience. They can support heavy equipment, overhead cranes, and storage systems that place significant weight on the framework. Many industrial buildings also use wide clear spans to eliminate the need for internal columns. That uninterrupted space simplifies production flow and allows for easier equipment placement.

Manufacturers in industries like aerospace, large-scale assembly, and metal fabrication tend to benefit from this setup. These applications often involve moving heavy materials or installing complex machinery that would be difficult to accommodate in a traditional framed building. In facilities where layout efficiency and load-bearing capacity go hand in hand, steel construction offers both without adding unnecessary complexity.

The adaptability of industrial metal buildings plays a major role in their appeal. High ceilings and open interiors accommodate things like conveyor lines, automated machinery, and bulk storage without having to work around support structures. This kind of design makes it easier to configure a workspace that fits specific processes, whether that means installing robotic arms or allocating zones for inspection and packaging.

Because these buildings are modular, it’s also possible to expand or reconfigure them as operations grow. In an environment where production methods change quickly, the ability to modify the space without major reconstruction is a clear advantage. This flexibility also makes them useful beyond core manufacturing, supporting a wide range of commercial steel building solutions like packaging lines, supply storage, or shipping operations.

Compared to traditional building methods, industrial metal buildings can be completed on a shorter timeline. The materials arrive ready to assemble, and much of the engineering is handled in advance. While actual timelines vary depending on the scale and complexity of the project, it’s not unusual for a steel building to be finished in a matter of months, rather than a year or more.

This time savings often translates to fewer delays in getting operations up and running. Facilities can open sooner, workforce training can begin earlier, and clients or distributors may benefit from quicker production cycles. In industries with tight margins or seasonal demands, faster setup can offer an operational edge.

The earlier a facility becomes operational, the sooner production can begin and ROI starts to improve. Time lost during construction often leads to ripple effects across procurement, staffing, and customer contracts. Minimizing that lag time through a more predictable building process makes a real difference in project outcomes.

Manufacturing environments are often demanding. From heat and vibration to chemical exposure, buildings in these settings need to hold up over time. Steel structures tend to perform well in these conditions, especially when combined with insulation packages and protective coatings.

Facilities dealing with paints, solvents, or processing byproducts often require special wall panels, rust-resistant fasteners, and adequate airflow systems. These features help reduce corrosion risk and maintain air quality, which can be important both for equipment lifespan and worker safety. In colder climates or temperature-sensitive operations, insulation and climate controls help maintain consistent performance.

Features like reinforced fasteners, weather-resistant panels, and integrated ventilation can help a facility maintain performance standards without requiring frequent repair. In industries where downtime is expensive, durability becomes part of the operational equation.

Industrial projects typically face a long list of building codes and regulations. These might include local wind load requirements, fire safety standards, energy efficiency targets, or environmental considerations. Designing a structure that meets these criteria without overbuilding takes experience and careful planning.

Some projects benefit from a more integrated approach, where ventilation systems, electrical layouts, and safety features are considered during the design phase. This can reduce revisions later and improve coordination between construction teams and permitting offices.

Even factors like egress points, fire suppression systems, or dock alignment can affect final approval and operational flow. When those elements are built into the structural plan rather than added as afterthoughts, compliance becomes less of a hurdle and more of a natural part of the build process.

Industrial metal buildings have earned their place in modern manufacturing for practical reasons. They offer the kind of structural integrity, design flexibility, and project speed that industrial operations often require. As production methods continue to evolve, these buildings provide a framework that can adapt along the way.